Radial Arm Saw

October 12, 2021—And where I'm at on the Hype Cycle (tools)

I recently purchased a radial arm saw (RAS) from Craigslist.

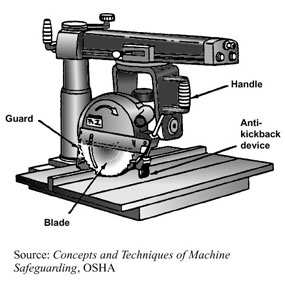

Here’s almost what it looks like:

Image from Wikimedia Commons

I can’t post a picture of what it actually looks like because it’s made of a material that’s too difficult to photograph under the temperatures and pressures I can achieve in my garage.

Just kidding. I can’t post a picture of it because it’s in pieces right now.

But I’ll tell you how it works. The long thing at the top is called the “arm”. You can pull the spinning blade down that arm and through your fingers and also through the thing you want to cut. That kind of cut would usually be called a “crosscut”.

Mine runs blades 10” in diameter—a 5” radius. The blade is attached directly to the motor which takes up some space. So in theory it can cut something up to ~3” thick.

What’s neat about a RAS is how many ways you can turn the blade. You can rotate it in all three axes. Obviously the blade spins around as it cuts, so that’s one axis. And you can rotate the motor in the other two axes. So basically you can put the blade at any angle you want. And the arm goes up and down and can be rotated, too. It can sort of do the job of two or three other dedicated tools. A RAS is supposed to be very flexible.

This kind of saw was very popular a few decades ago. Probably because it’s so versatile and because it takes up so much less space than the two or three other tools it can sort of replace. That’s why I bought this used one. Since then they’ve fallen out of favor. They have the reputation of being too dangerous. But the people who love them and still have all their fingers say they’re not too dangerous if you keep it dialed in and use it correctly.

My RAS is three decades old. I’m not sure how many decades the manufacturer of my RAS produced them. It’s not from DeWalt who started making them in the mid 20s (as in the one-hundred-years-ago 20s), but still I guess thirty years old is pretty young for the design.

But thirty years is plenty of time for there to have been a recall for too many fingers cut off. Which brings me back to why my RAS is in pieces.

One way I plan to help myself keep my fingers is by fine-tuning all its adjustments. I completely disassembled it, cleaned and degreased the parts that looked important, and as I put it back together I am adding new grease. I’m also tightening things that shouldn’t be loose, making sure I don’t over tighten things that only need to be snug, and sanding down spurs where there shouldn’t be any.

Now I’m getting to the point where I can start aligning the blade to the table, to the fence, and to the arm. I’ll also align the table to the arm and the arm to the table. Then I’ll dial it all in with several strategic cuts.

The idea is that a blade that cuts straight, true, smoothly, and precisely will not only be free of dramatic emergency room visits, but it’ll also make cuts that look really nice.

Speaking of the strategy and technique for aligning a RAS, I cannot recommend a book on this subject more highly than Jon Eakes’s Fine Tuning Your Radial Arm Saw. His book has been invaluable. It has tons of tips and tricks for getting it set up simply and effectively, and he walks you through a series of steps with enough detail to understand why without bogging you down in the minutiae. The pictures for my brand’s RAS are a little dated (the design must have changed) but you can still figure out how to apply the principle because he explains why it works.

I also got some new blades. The blade that came with my purchase could very well be original to the saw. It wasn’t used heavily, but still it’s not super clean. Plus it has the wrong angles for crosscutting. Having a nice sharp clean blade with good angles is supposed to be another way to keep your fingers.

Where am I on the Hype Cycle? Things keep looking brighter, so I must not have crested the Peak of Inflated Expectations yet.